Sandbot 200L - SANDBOT DUST-FREE SURFACE CLEANING

About our product

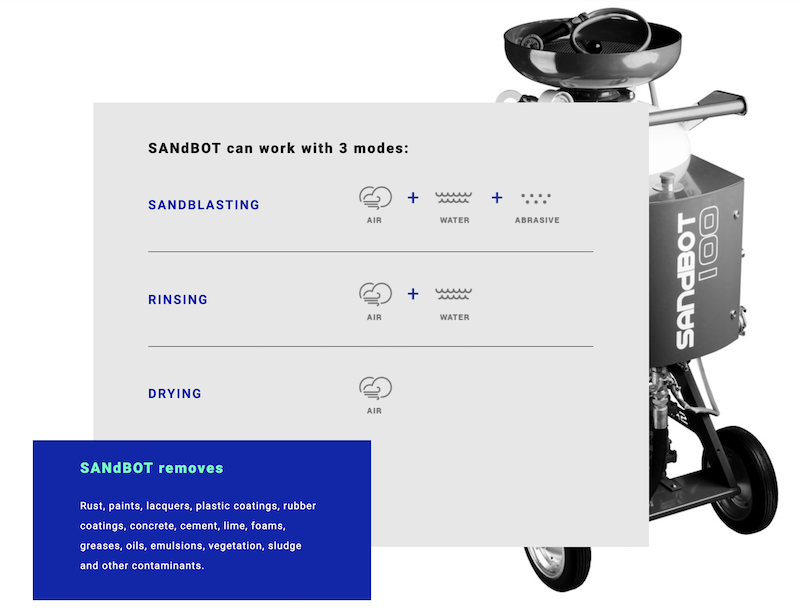

The SANdBOT wet sandblasting machine is designed for the dustless cleaning of a wide variety of technical surfaces. The machine uses the dustless hydro-abrasive system consisting of an innovative abrasive stream technology. The surfaces are precisely and safely cleaned using a high-pressure stream of water with an added abrasive agent.

High cleaning performance, low utilities and consumable parts costs and a small compressed air demand, makes SANdBOT extremely economical device. Compared with traditional methods, such as dry sand blasting, sodium and dry ice cleaning or even 2500-3000 bar pressure washer, SANdBOT is cheapest solution currently available on the market.

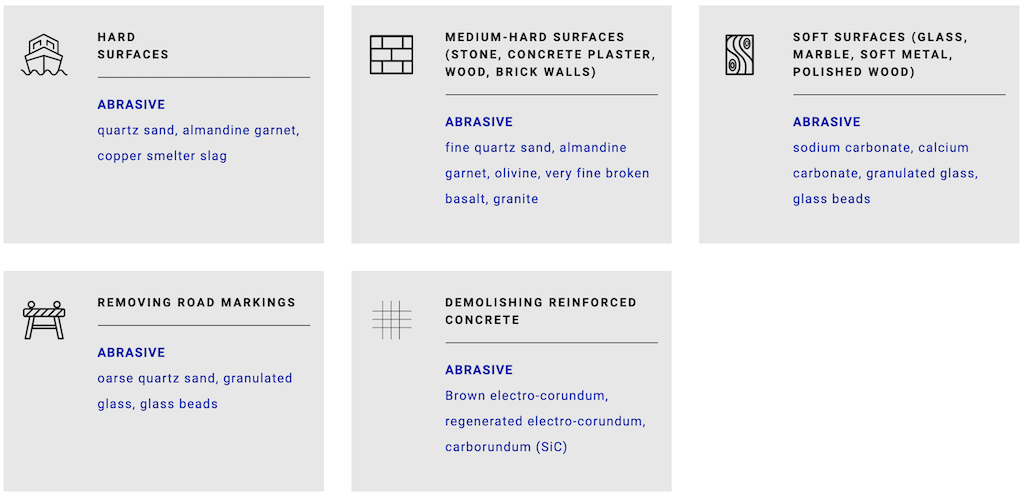

THE MOST POPULAR ABRASIVES ARE:

1. GARNET 2. QUARTZ SAND 3. COPPER SMELTER SLAG 4. ELECRO-CORUNDUM

Quartz sand can also be used, whether dry or wet – unlike in traditional sandblasting, where dry sand is prohibited.

The SANdBOT dustless cleaning system utilizes an innovative, patented (PL 218148) dustless hydro-abrasive system . The system’s wide range of applications makes SANdBOT the most versatile and efficient wet sandblasting machine on the market!

Application Examples can be found on Resource TAB

Shipyards and the marine sector

The mining industry

Construction

Metal works

Road construction

Renovation of urban areas, protection of historic buildings and sites

Jobs you can do with SANdBOT:

Building walls, reservoir walls

Roads and pavements

Casting moulds

Steel structures and components

Renovation of metal parts

Asbestos removal

SANdBOT is the answer to the challenges faced by wet sandblasting contractors. Our machine was designed to provide high-performance, dustless wet sandblasting in accordance with the highest health and safety standards. The wet sandblasting machine does not emit dust, and reduces sparking to an absolute minimum.

Metal works

The sandblasting machine removes all contamination from the surface of the steel structures. The device removes a wide range of paints and contaminants from steel elements: mini, lead, tar, chrome, cadmium-containing and other coatings such as: concrete, rust, patina, bitumen, rolling mill, chlorides and salts. soluble.

SANdBOT is a must have for the companies that provide painting services.

Shipyards and the marine sector

A wet sandblasting machine may be used in the prefabrication and construction of boats and ships. The SANdBOT EX ensures workplace safety in explosion-endangered areas, making it the dedicated machine for shipyard workers.

The SANdBOT machine is mobile and easy to operate, making it ideal for maintenance and repair work at sea. SANdBOT technology can be successfully applied on any boat or ship, whether built of steel, fiberglass, wood, or aluminum.

The mining industry

SANdBOT's work is not producing sparks. The device can perform its tasks in mines and offshore platforms. This makes leading contractors of hydro-abrasive works choose our brand's sandblasting machines.

Our technology works well in the oil and gas extraction and processing industries, the chemical industry on mining platforms and in mining.

Construction

Construction is a natural environment for SANdBOT. Demanding applications such as cleaning concrete for repair, pickling, inspection of steel infrastructure or for demolition purposes are the challenges for which we have created our sandblasting machines.

In the case of concrete surfaces, the hydro-abrasive system ensures perfect preparation of anti-slip surfaces for paint or anti-corrosion coatings. SANdBOT speeds up renovation works and the disposal of lead and asbestos.

Road Construction

During the construction and renovation of roads and bridges, SANdBOT sandblasting machines ensure safety and efficiency of operation. As an alternative method of removing horizontal markings, the hydro-abrasive system ensures the safety of workers and road users while maintaining high work efficiency, no dust, smoke, blemishes or burns on the road surface are generated. SANdBOT is a support in the implementation of the most difficult tasks, such as surface cleaning during repairs.

Renovation of urban areas, protection of historic buildings and sites

SANdBOT removes graffiti and other deposits from concrete surfaces, metal surfaces, plaster, stones, sandstone, marble, metal, asphalt, paving stones and bricks.

The device will obtain the desired effect of a clean wall, no matter what type of paint the "artist" used. SANdBOT works well in the renovation of buildings, monuments, statues and even railway carriages and other means of transport.

Car Workshops

SANdBOT is perfect for car workshops, for removing the paint coating from the car body, cleaning the chassis, rims, drive shafts, axles, etc.

Appropriate adjustment of the pressure of the working hose and the size of the abrasive to the cleaned surface makes the applications practically unlimited.

Copyright © 2017 - 2024 by Indpart.com. All Rights Reserved.